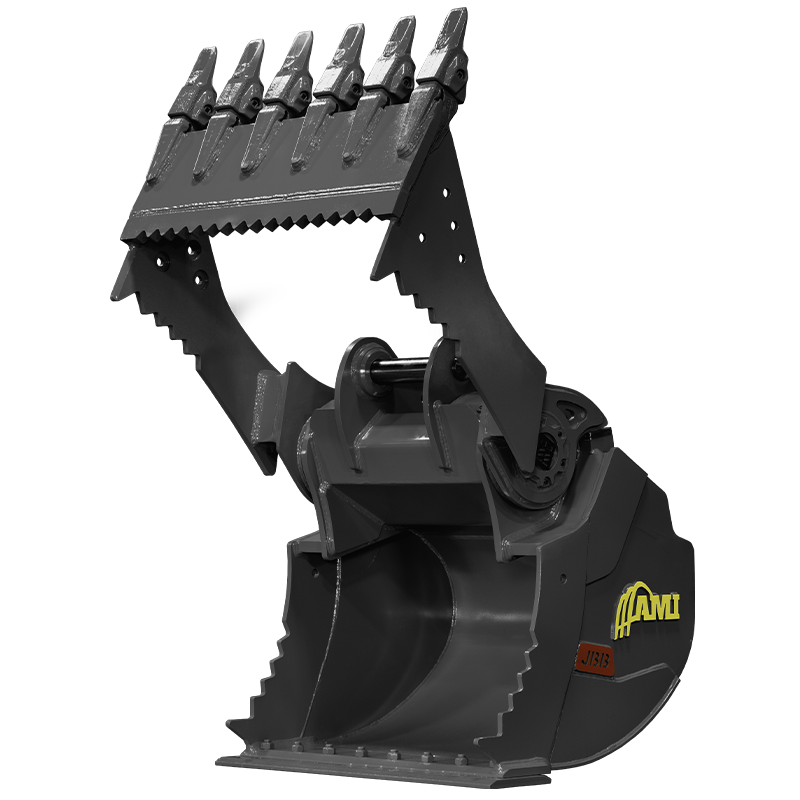

RAMCAM™ TECHNOLOGY

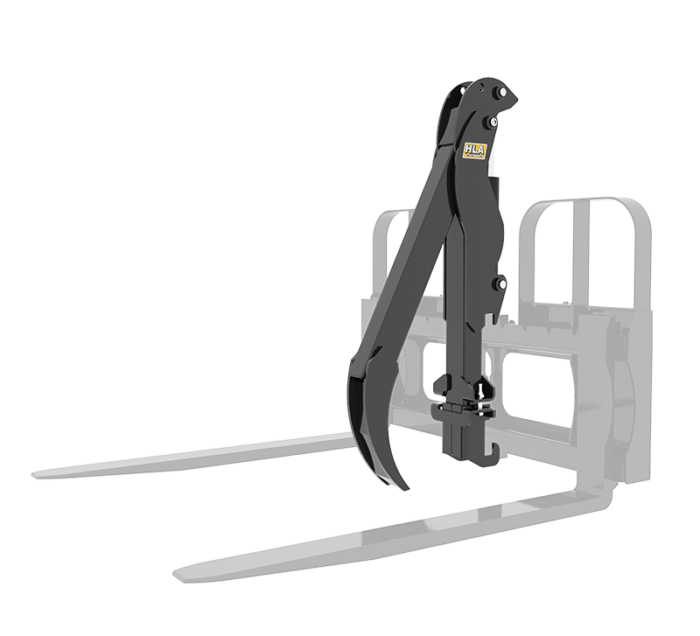

RAMCAM™ is a revolutionary new drivetrain that allows for mechanical rotation using hydraulic cylinders enclosed within a protective casing.

FULLY ENCLOSED HYDRAULIC CYLINDERS

Ingeniously designed, the RAMCAM™ drivetrain efficiently transfers energy from standard hydraulic cylinders, through a splined camshaft and into the Jawbone thumb for a tight grip on every load. And with RAMCAM™ completely enclosed, all components are fully protected at all times.

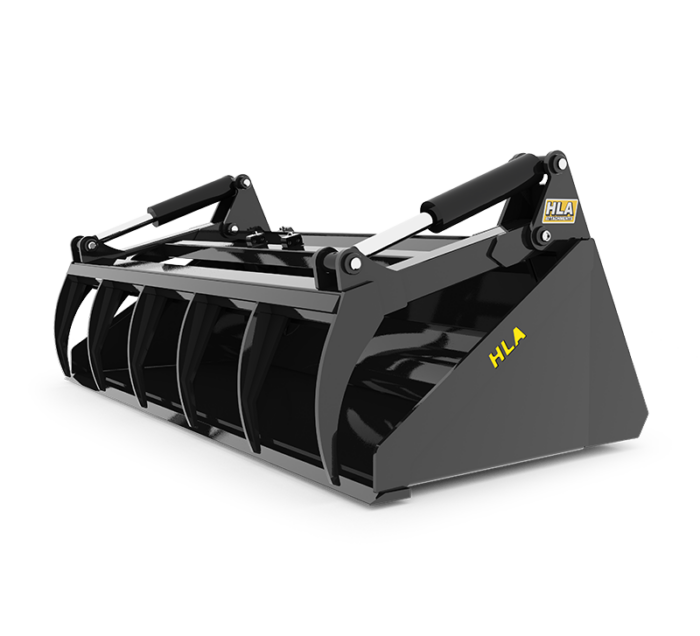

CONSTANT GRIP

Confidently handle heavy and awkward loads with the superior grip of the Jawbone’s integrated thumb. For demolition work requiring picking, sorting and transferring, the Jawbone strongly grips the load and holds it securely throughout the full rotation of the bucket, all the way to roll out. The Jawbone also takes out the guesswork of trying to control both thumb and bucket at the same time, providing a safer worksite and reducing hydraulic line failure from over-pressure.

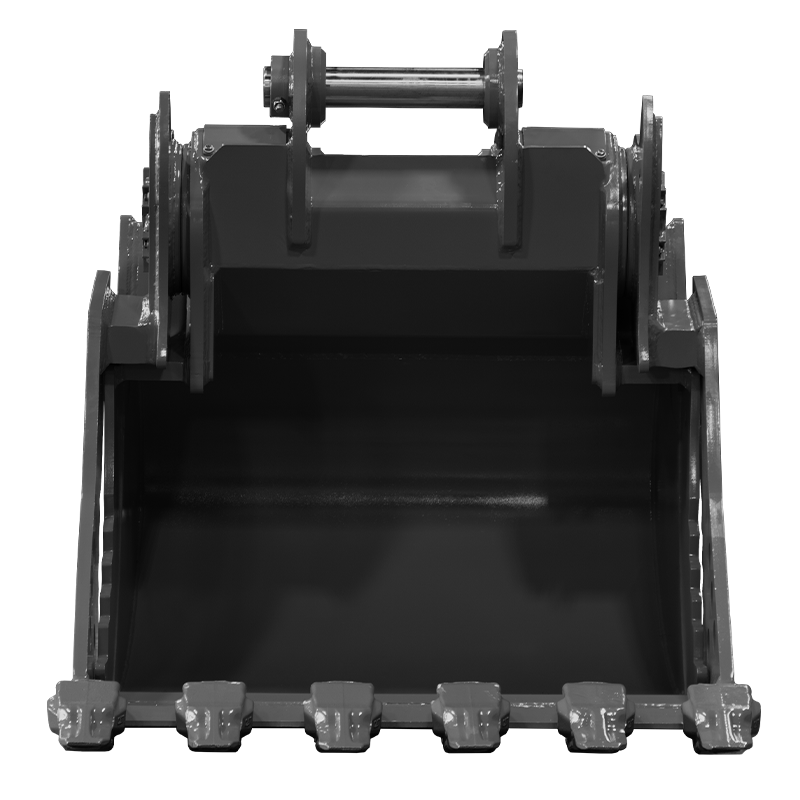

HEAVY DUTY CONSTRUCTION

Aggressive serrated side plates come standard for maximum grip. The Jawbone is built using Hardox 450 steel.

GREASE BANK

With all the grease points now protected, the Jawbone powered by RAMCAM™ features a grease bank for simple and routine maintenance.